114m² cleanroom for subsea telecommunications technology production

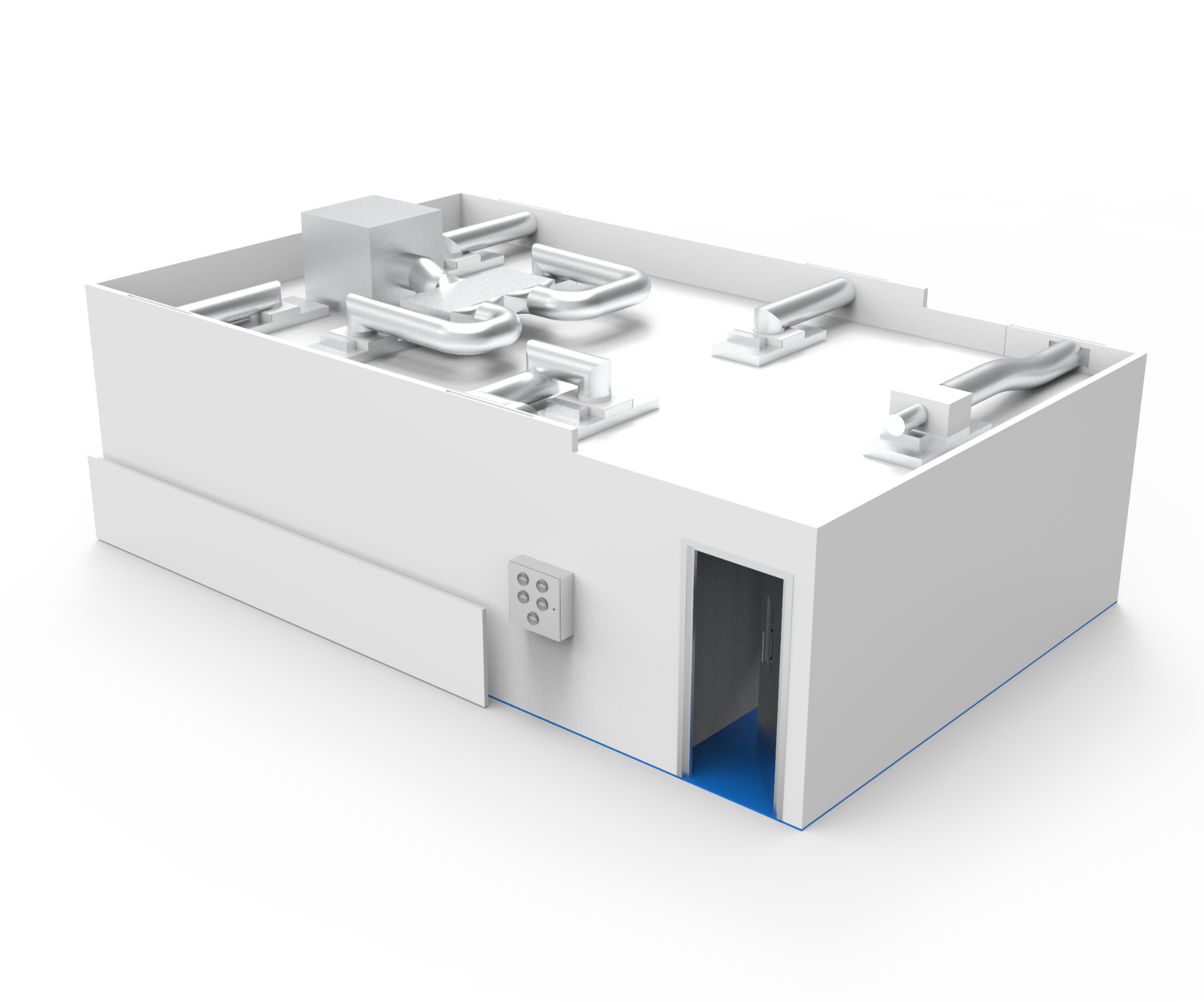

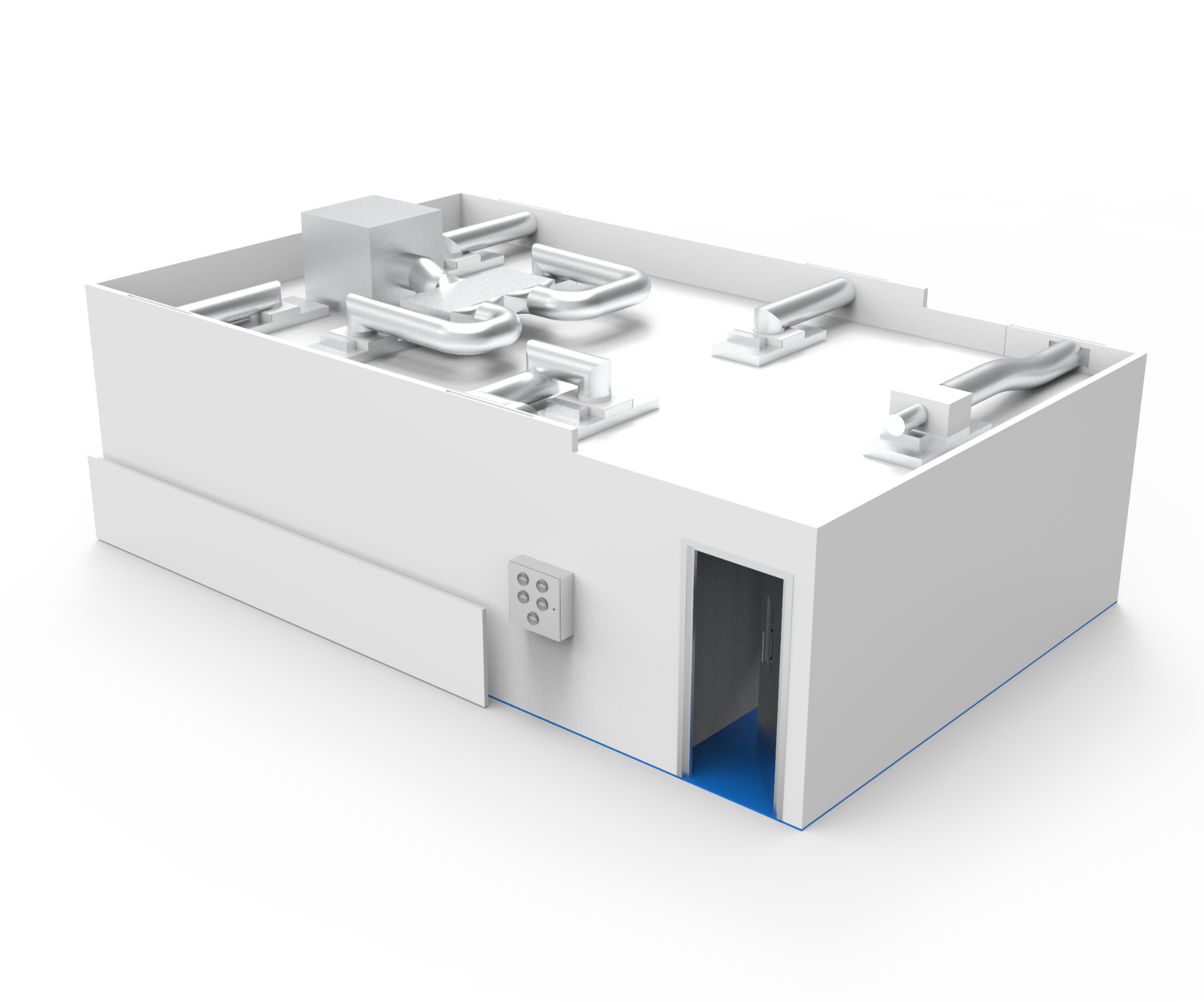

Connect 2 Cleanrooms was appointed to design and build a 114.7m², ISO class 7 monobloc cleanroom with decentralised air handling and full temperature control for the production of innovative subsea telecommunications equipment.

Key features of the cleanroom

114.7m² cleanroom

Decentralised air handling system

Temperature and humidity control

Two sliding doors

The client

Xtera Ltd is an innovative provider of subsea telecoms solutions and technologies with over 30 years’ collective industry experience. Designing and delivering underwater networks, Xtera’s equipment plays a vital role in transporting high volumes of data traffic between countries and continents through submarine cable systems, repeater units, and optical amplifiers.

With increasing demands for speed, scalability, and flexibility, Xtera Ltd was looking for a cleanroom solution to support their future innovations including robotics, automation, and smarter design.

The project

Xtera Ltd approached Connect 2 Cleanrooms to introduce an additional cleanroom manufacturing facility for their UK-based engineers. With a need for fast prototyping and hands-on innovation, the new cleanroom facility supports the production of specialised products and complex units.

A key aspect of this cleanroom’s design was maintaining humidity levels of ≤40% R/H and temperature controlled to 20°C (+/- 2°C). This was to prevent moisture contamination and corrosion of optical fibres found within subsea components and technologies, whilst maintaining an ISO class 7 operating environment.

We installed a decentralised air handling system with sensors in the air return panels to monitor the temperature as the air leaves the room. This ensures that temperature is maintained within the specifications and gives Xtera the flexibility to make easy adjustments to one area of the cleanroom without affecting the entire system. We incorporated two sliding doors between the air lock and main area of the cleanroom to allow easy and convenient transfer of materials and components.

Installation

Our engineering team was onsite for approximately 5 weeks installing the new facility at Xtera Ltd. The cleanroom was constructed using monobloc versatile flush panels with three semi-flush windows, maintaining high levels of cleanliness and particle control.

During the handover phase, our engineers validated the cleanroom to ISO class 7. The cleanroom was equipped with a fully walkable ceiling system, allowing personnel and engineers easy access via a fixed cat ladder for maintenance and ongoing compliance throughout its lifecycle.

Following the cleanroom’s build and installation, Xtera Ltd needed to quickly and efficiently equip the new facility with tools and consumables, enabling them to kick-start their production processes. Our Cleanroomshop experts supported Xtera Ltd with implementing some cleanroom furniture, cleaning and disinfection wipes, and cleanroom user essentials including coveralls and overshoes.

Xtera Ltd testimonial

Joerg Schwartz (Chief Partners and Solutions Officer)

Start a project with us

Our design and build specialists have experience working with customers in all kinds of industries on a global scale, achieving great results time and time again. We’d love to work with you as well!