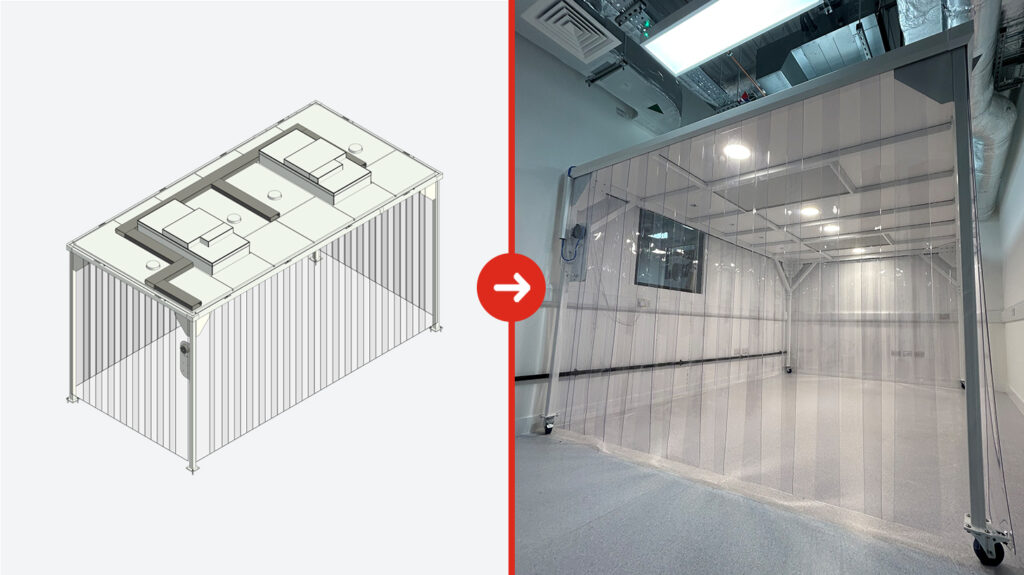

12m² predesigned softwall cleanroom for microneedle tattoo patch production

Connect 2 Cleanrooms was appointed to deliver a 12m², ISO class 7 predesigned softwall cleanroom with HEPA filtration for the production of innovative body-art solutions.

Key features of the cleanroom

12m² predesigned softwall cleanroom

Validated to ISO 14644 class 7

x2 HEPA fan filter units and lockable castors

Installed within 48 hours

Flexible and scalable solution

The client

Founded in 2021, CipherX is biotech company developing next-generation microneedle technologies for lifestyle, cosmetic, and future medical applications. Their flagship MicroDot tattoo platform uses dissolvable biopolymer microneedles to deliver tattoo pigment into the skin in a precise, painless, and low-risk manner, combining advances in materials science with contemporary body-art practice.

As CipherX progressed from early prototyping toward commercial readiness, the company identified the need for a controlled cleanroom environment to support the fabrication and assembly of its microneedle products.

The project

As a growing business with a unique product offering, CipherX needed a controlled environment solution that was flexible, adaptable, and cost-effective. CipherX initially approached Connect 2 Cleanrooms for a hardwall cleanroom solution to be installed in their existing office space. However, following a detailed consultation with our design and build experts, it was advised that a softwall cleanroom from our predesigned range was better suited to their requirements.

A key aspect of this cleanroom design and build project was the ability to easily dismantle, move, and expand the production environment along with company expansion. Predesigned softwall cleanrooms are designed to be scalable, versatile, and future proof; ideal for introducing or expanding controlled environments within budget and without impeding on quality.

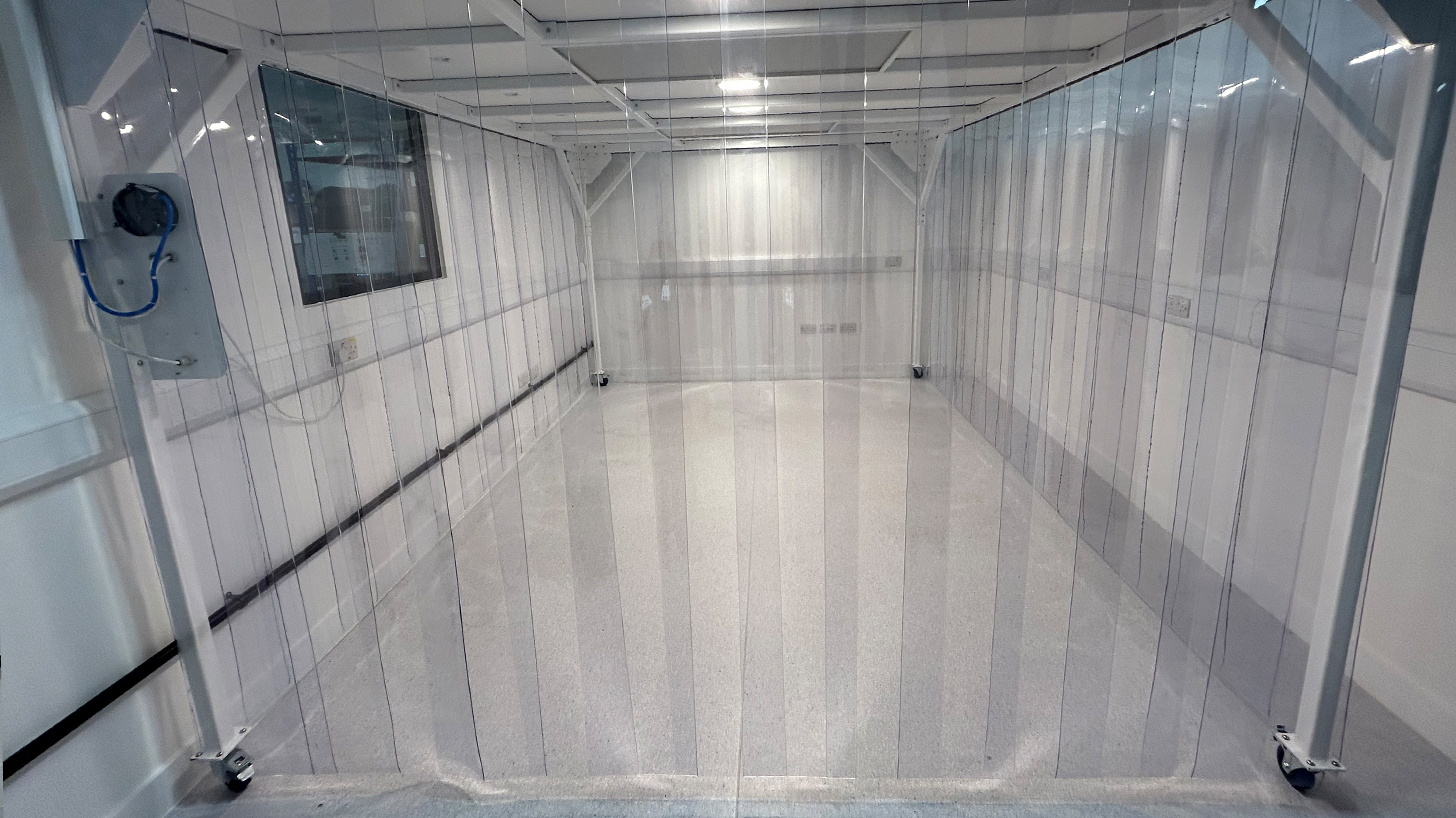

The 4m x 3m predesigned softwall cleanroom with two HEPA fan filter units provides CipherX with an optimal production space for their innovative solutions and regulated airflow to reduce airborne particles.

Installation

Speed and flexibility were main priorities for CipherX’s design and build project, and a predesigned cleanroom accommodates these requirements. The softwall controlled environment was installed within CipherX’s facilities in just 48 hours, allowing them to get up-and-running with their applications.

Following installation, our engineers validated the cleanroom to ISO class 7, enabling CipherX to evidence their commitment to cleanliness and product integrity.

CipherX Testimonial

“Connect 2 Cleanrooms helped us solve a challenging problem that was integral to our product. We required a clean, controlled environment for the pilot production of our microneedle product, but also needed a flexible solution compatible with our current facilities. As an early-stage start-up, we were also conscious of how this solution could be relocated or adapted for future scale.

Through their thorough consultation process, Connect 2 Cleanrooms were able to deeply understand our requirements and recommended the best solution. In our case this was a softwall cleanroom solution. Their engineers were professional, efficient, and assembled and validated the cleanroom within just two days, with minimal construction noise so as not to disturb the workflow of our neighbours. We had a very positive experience and would not hesitate to recommend Connect 2 Cleanrooms to others.”

Start a project with us

No matter your industry, we take the complexity out of cleanroom management by providing trusted solutions that enable you to maintain your critical environments with confidence.