Cleanroom Furniture Fit-Out for the Production of Agricultural and Marine Autogenous Vaccines

Connect 2 Cleanrooms was appointed to furnish an existing cleanroom environment in line with GMP Annex 1, improving and optimising the production of autogenous vaccines for agricultural and marine life.

Key features of the furniture fit-out project

GMP grade B compliant

Custom-made furniture with 316 and 304 stainless steel

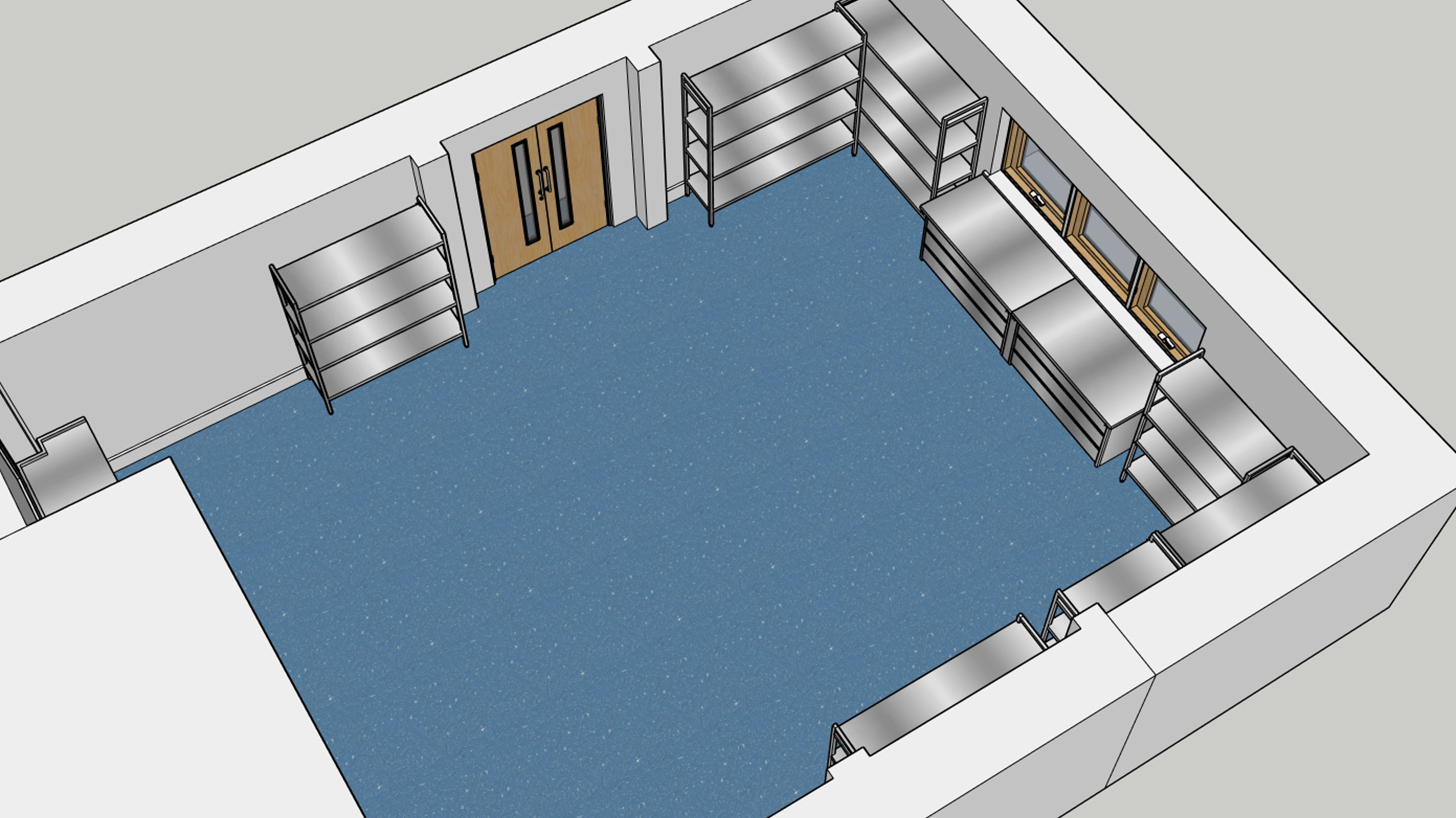

3D mapping and modelling designs

Cleanroom lifecycle provider

The client

Ceva Ridgeway are a VMD- (Veterinary Medicines Directorate) licensed manufacturer of autogenous vaccines, produced for agricultural and marine life. Autogenous vaccines are prepared from a pathogen extracted from a host animal/s which is then used to treat other infected animals.

Following updates to Good Manufacturing Practice regulations in 2021, all vaccines manufacturers are now governed by GMP standards. During this time, Connect 2 Cleanrooms’ GMP and Regulatory Governance team supported Ceva Ridgeway with optimising their workflows and processes, along with advising on suitable clothing and disinfectant consumables to ensure they were consistently operating in line with GMP Annex 1.

The furniture fit-out project

In 2022, Ceva Ridgeway were looking to replace non-GMP-compliant furnishings within their manufacturing and storage areas. This would not only support their efforts with continually demonstrating compliance with GMP grade B but also optimise their production processes.

This furniture fit-out project included both standard and custom-made furniture using 304 and 316 stainless steel for GMP compliance:

- Stainless steel tables

- Stainless steel drawers

- Stainless steel cupboards

- Stainless steel sinks

- Stainless steel racking

- Stainless steel transport trolleys

- Gas cylinder storage unit

During this time, Ceva Ridgeway also opted for GMP training to ensure their cleanroom operators were informed and up to date with GMP guidelines, allowing them to confidently demonstrate to the VMD that they meet GMP compliance.

Fast forward to 2025, Ceva Ridgeway introduced an additional storage facility to support their expanding production. Currently, this new area isn’t mandated under GMP guidelines, and whilst they could have opted for standard storage and furniture from a general supplier, it was important for Ceva Ridgeway to maintain consistency throughout their entire applications and implement future-proof solutions that support additional expansion.

Our cleanroom furniture experts worked closely with Ceva Ridgeway’s team to deliver the most suitable solutions for the project. During a site visit to their facility in Compton, we conducted a thorough assessment of their space and requirements. Using 3D mapping and modelling, we provided a detailed visualisation of the proposed layout, enabling Ceva Ridgeway to clearly envision their new facility.

Following two design amendments to refine the process flows, the final concept included custom-made storage solutions and furnishings using 304 stainless steel to sustain increased weight and suit their unique processes.

The primary supplier of cleanroom consumables, validation, and expertise

Over the past four years, Connect 2 Cleanrooms continues to be the primary supplier of Ceva Ridgeway’s cleanroom consumables, GMP training, consultation, and validation requirements. By utilising our suite of services as part of the cleanroom lifecycle, Ceva Ridgeway receive a one-stop-shop solution with consistency, expertise, and quality.

As a biotechnology business, Ceva Ridgeway requires regular, high-quality tools and products that support their applications and ensures compliance with GMP standards. Our consumables experts as part of Cleanroomshop supply a range of both sterile and non-sterile PPE, clothing, and disinfectant solutions via a Service Level Agreement – streamlining their supply chain, automating deliveries at a time and frequency that suits them, and provides them with exactly what they need, when they need it.

Ceva Ridgeway testimonial

“From the very word go, the whole Connect 2 Cleanrooms team have been a pleasure to work with and have around. The team were onsite for 4 weeks and nothing was ever a problem for them and every hump was carefully communicated and a solution was always found. The build was kept to schedule throughout and we were extremely pleased with the end product.”

Start a project with us

Our furniture and consumables specialists have experience working with customers in all kinds of industries on a global scale, achieving great results time and time again. We’d love to work with you as well!