Monobloc cleanroom for solid and liquid dose medicine production

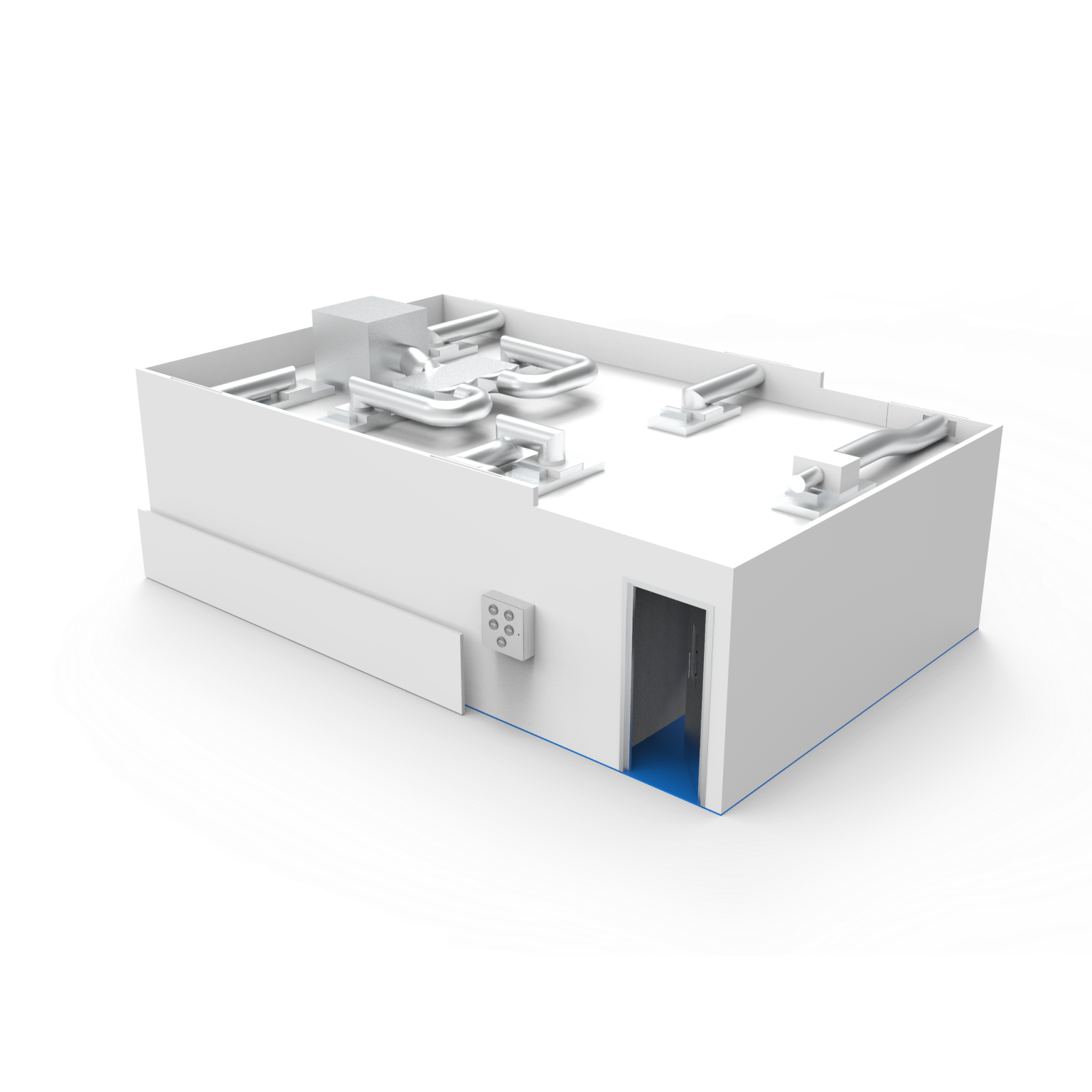

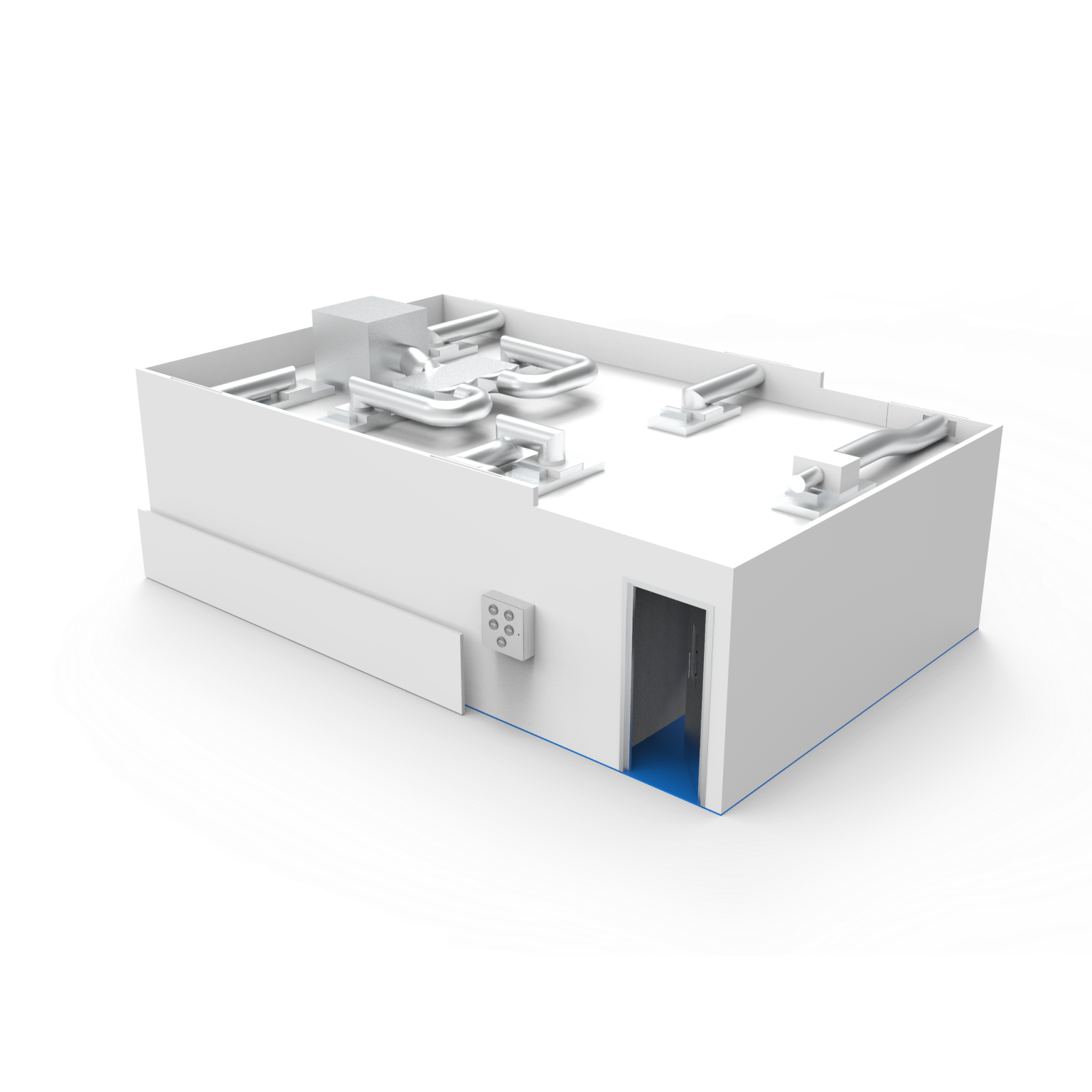

Cubic Pharmaceuticals is the first life science company in the UK to achieve a patented design for its novel continuous granulation process for processing water insoluble Active Pharmaceutical Ingredients (APIs) by means of hot melt extrusion (HME). Cubic Pharmaceuticals required a cleanroom suite, for the manufacture of solid and liquid dose medicines, and appointed Connect 2 Cleanrooms to build a 54m² monobloc cleanroom.

Key features of the cleanroom

54m² monobloc cleanroom

GMP grade cleanroom

5 areas for mixing, production, cleaning and dispensing

Off-site constructed for an efficient installation

Gallery

The client

Cubic Pharmaceuticals required a cleanroom suite, for the manufacture of solid and liquid dose medicines. Cubic Pharmaceuticals is the first life science company in the UK to achieve a patented design for its novel continuous granulation process for processing water insoluble Active Pharmaceutical Ingredients (APIs) by means of hot melt extrusion (HME).

With a unique continuous manufacturing process for processing most challenging APIs, its technology increases the solubility of ibuprofen to 80% within 15-20 minutes and 97% within 2 hours.

“We invented the manufacture of Ibuprofen through Hot Melt Extrusion, which is a world first”, says Saumil Bhatt, Cubic Pharmaceuticals. “We also use platform technology to manufacture another 30 different non-soluble molecules through Hot Dry Extruded Granulation.”

The project

The monobloc cleanroom suite encompasses 5 areas for mixing, production, cleaning and dispensing, plus a change area for operatives. It was off-site constructed for an efficient installation.

The cleanroom

“This GMP grade cleanroom has transformed Cubic Pharmaceuticals to a Contract Research Organisation (CRO), allowing pharma companies to benefit from our technology breakthroughs,” says Saumil Bhatt, Cubic Pharmaceuticals.

Cubic Pharmaceuticals testimonial

This GMP grade cleanroom has transformed us to a Contract Research Organisation (CRO), allowing pharma companies to benefit from our technology breakthroughs.

We used Connect 2 Cleanrooms because of the amount of projects they have delivered, the affordable cost and their track record of high quality work.

Start a project with us

Our design and build specialists have experience working with customers in all kinds of industries on a global scale, achieving great results time and time again. We’d love to work with you too!