Portable Cleanrooms

Portable cleanrooms are a unique and versatile controlled environment solution whereby the entire structure can be moved or relocated depending on the users’ requirements. They are often designed using a steel frame with PVC softwall curtain strips to create a barrier to the external environment and castors to allow for easy transportation.

Portable cleanrooms are becoming increasingly popular for industries that have limited production space and may only require a cleanroom for a limited time during the production process. They are also a useful solution for start-ups that have multiple processes that might require a controlled space, but budget restrictions mean they can only afford one cleanroom, allowing the same room to be used for multiple processes in different areas.

Why choose a portable cleanroom?

While static cleanroom builds have their benefits, portable cleanrooms have a distinctive and different set of attributes that make them ideal for certain situations. Some of the benefits of portable cleanrooms include:

Flexibility

Cost efficiency

Compliance

Speed of installation

Modular design

Types of portable cleanroom

Softwall cleanrooms: Built with the option of castors

Softwall cleanrooms offer the most simplicity as they can be wheeled around without having to deconstruct anything. They can be wheeled over one injection moulding machine, for example, while a part is being produced and then over another machine while another part is being produced, without having to invest in two separate cleanrooms. The relocation process can take a matter of minutes, making it the fastest portable cleanroom solution.

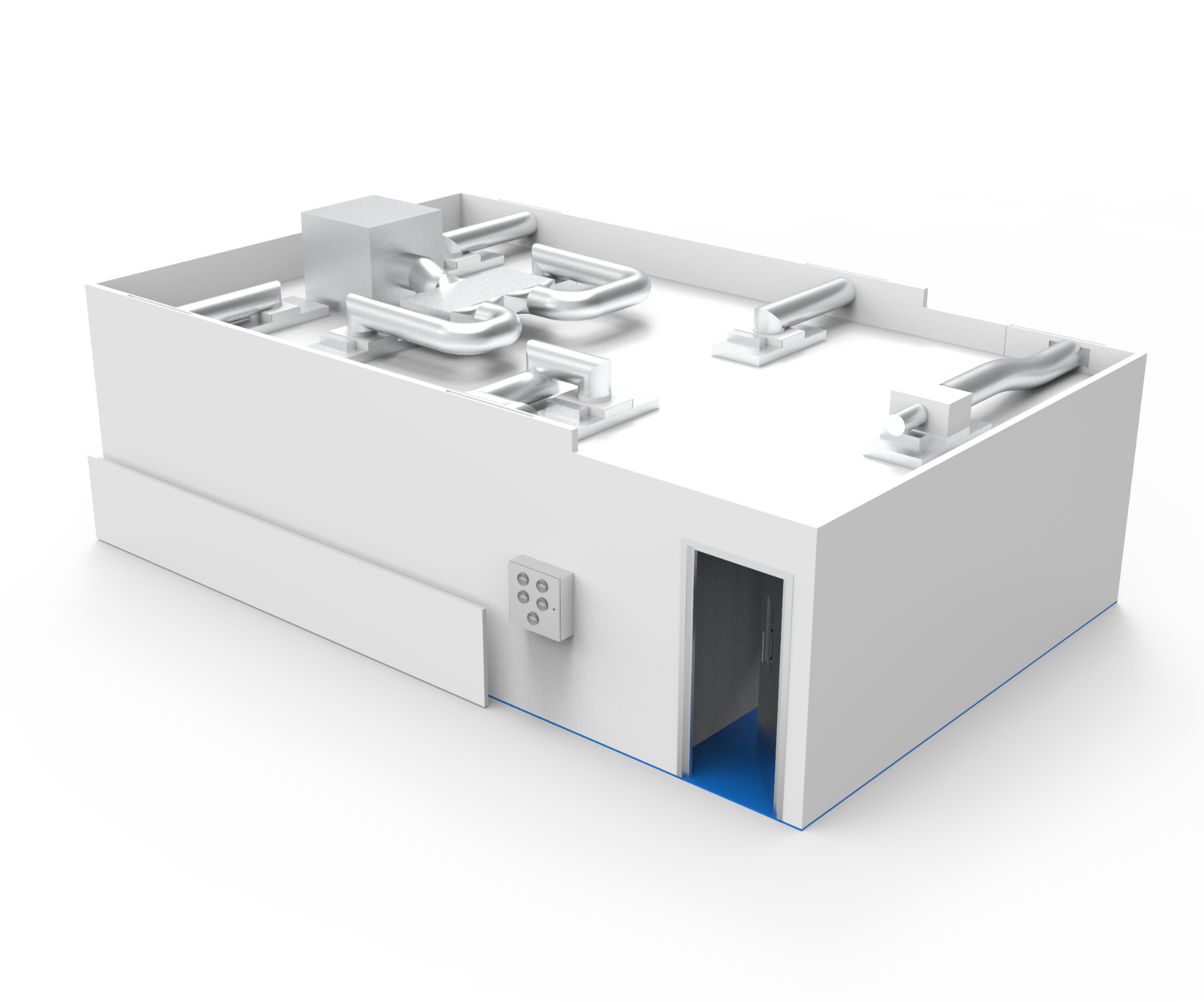

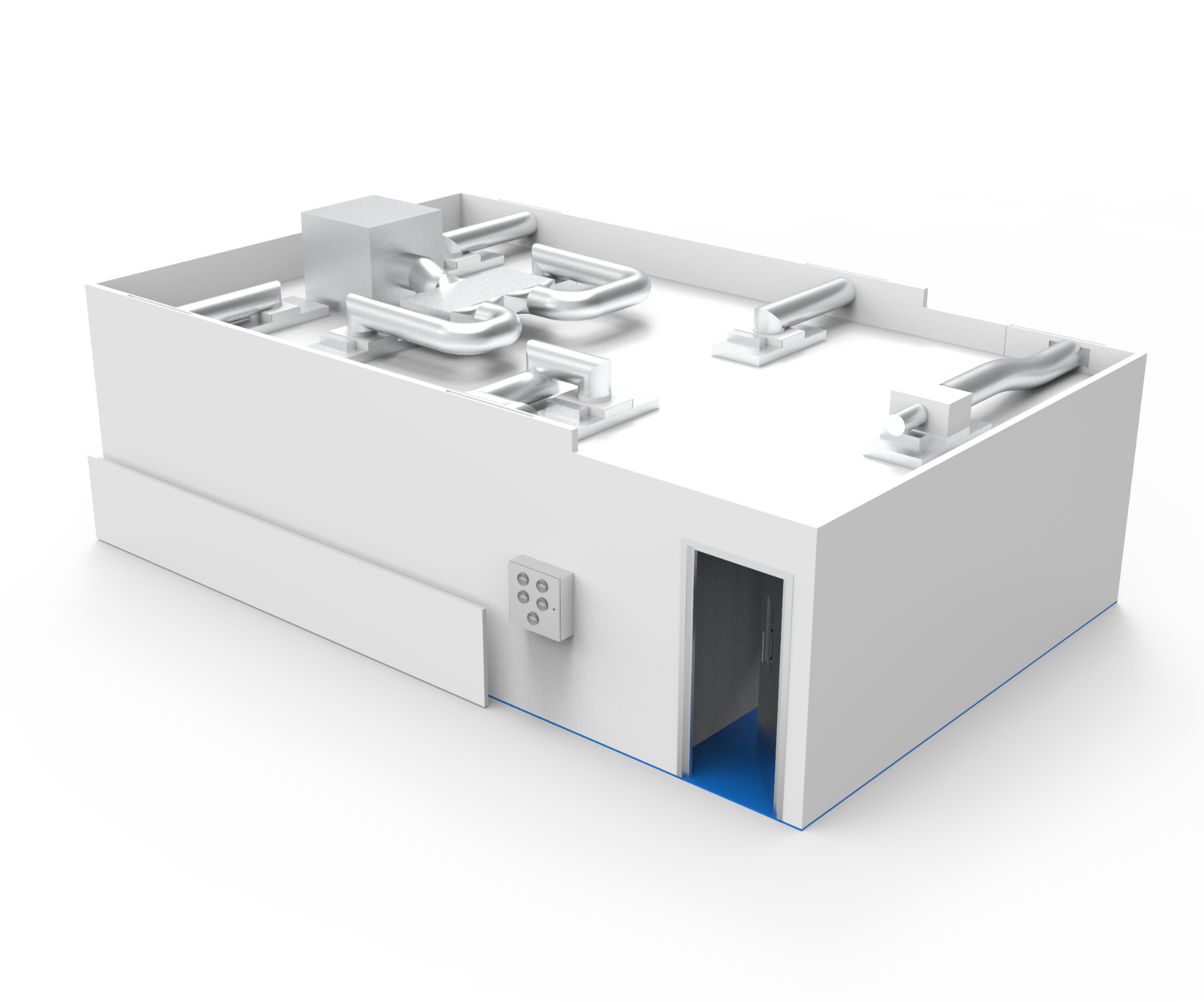

Hardwall cleanrooms: Easily deconstructed and reconstructed

Hardwall cleanrooms are an ideal option for someone looking for a portable cleanroom that isn’t intending on moving it regularly, perhaps every 6 – 12 months. Our predesigned hardwall cleanrooms can be installed and constructed in as little as 48 hours, so while transportation is not as fast as a softwall solution on castors, it still provides enough flexibility for those looking for something that has the option of being relocated when needed.

Key industries that might require a portable cleanroom solution

There are multiple industries that might require a portable or mobile cleanroom and we’ve completed projects of differing specifications in all of the following industries, plus many more.

Vape production – Cleanrooms prevent contamination during liquid filling or cartridge assembly. It is important that cleanliness is maintained in a controlled environment to ensure purity and quality control of the substance within.

Injection moulding – Precision medical components and clean plastic parts must be produced in a contaminant-free environment. However, one machine might produce multiple parts, some requiring a clean environment while others might not, meaning a portable cleanroom is the ideal solution for such a situation.

Packaging plants – Packaging plants that produce and package a wide range of products such as food, pharmaceuticals, electrical components and cosmetics might utilise a portable cleanroom to maintain product integrity with an on-demand setup.

Electronics manufacturing – The presence of dust and particles within an environment where electronics and sensitive products are being manufactured could result in catastrophic product failure. Adaptable and mobile cleanrooms allow the production line to be adjusted as required and processes protected to ensure optimum product quality.

Related case studies:

Optimould

Connect 2 Cleanrooms installed a localised modular cleanroom to house an individual machine. Optimold now has 13 injection moulding machines, of which seven are enclosed in modular cleanrooms. Having the cleanrooms on castors means they can be wheeled away from the machine to give access to change tooling easily.

Cern

Collaborating with CERN scientists, Connect 2 Cleanrooms designed a telescopic cleanroom with three moveable modules that extend on guide rails from a closed position, tripling the floor space.

Lancaster & Morecambe College

Connect 2 Cleanrooms was appointed by Lancaster & Morecambe College, to provide a predesigned cleanroom to be used in its Engineering Department, to allow students the opportunity to gain experience of working within a cleanroom environment.

Start a project with us?

Our design and build specialists have experience working with customers in all kinds of industries on a global scale, achieving great results time and time again. We’d love to work with you as well!