What is Cleanroom Validation?

Maintaining a cleanroom and ensuring compliance can be challenging, especially when you’re also responsible for day-to-day operations of the working environment and the production line within it.

We are here to support you from day one of your cleanroom project, and in this blog we’ll explain what cleanroom validation is, its importance and what it involves.

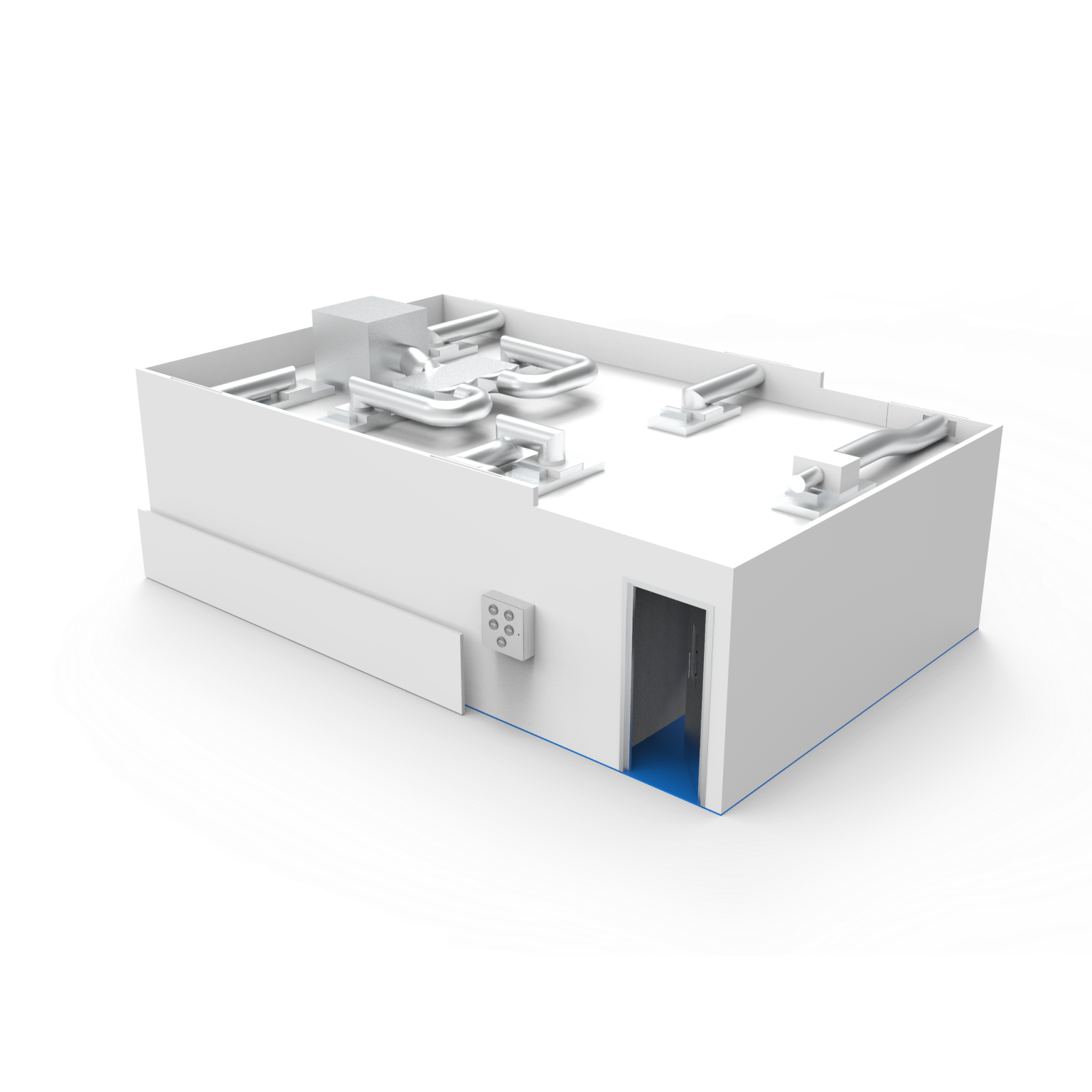

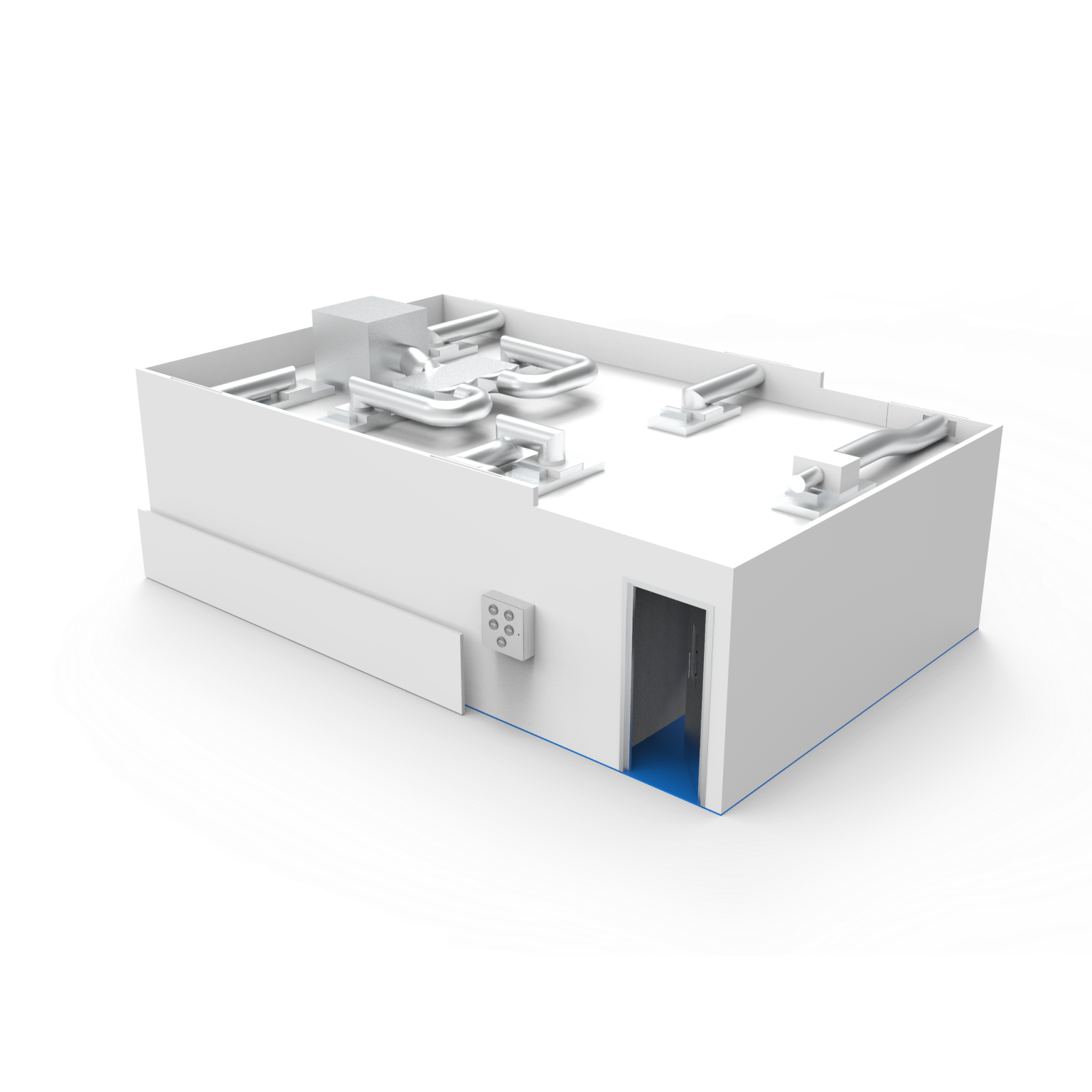

Understanding cleanrooms

Before we explain what cleanroom validation is, it’s important to initially understand what a cleanroom is and how it is classified.

According to EU GMP Annex 1, ‘a cleanroom is a room designed, maintained and controlled to prevent particle and microbial contamination of drug products. Such a room is assigned and reproducibly meets an appropriate air cleanliness level.’

Although the above explanation of a cleanroom refers specifically to the contamination of drug products, cleanrooms are used in a variety of industries to prevent the contamination of the processes within, such as injection moulding, semiconductors, automotive and aerospace.

Cleanrooms are classified, based on the maximum allowable levels of particulate contamination per cubic metre, as outlined in standards such as ISO 14644 and GMP (Good Manufacturing Practice) guidelines.

What is cleanroom validation?

Cleanroom validation is the process of verifying and documenting that a cleanroom operates within its designed parameters. It involves conducting a series of tests to ensure that the cleanroom meets the mandatory environmental constraints, primarily ensuring that the number of particles per m³ of air is within the required tolerance to satisfy the desired ISO or GMP classification

In short, cleanroom validation ensures that cleanrooms meet strict regulatory standards, performing as intended to protect products, processes and end-users.

Why is cleanroom validation so important?

Validation is a critical process within industries that require highly controlled environments, such as pharmaceuticals, healthcare and electronics.

Much like an MOT for your car, which ensures your car is fit for driving on the road, validation ensures your cleanroom is fit for the processes being undertaken within it.

It provides assurance that the cleanroom consistently maintains the specified conditions for air cleanliness, temperature, humidity and pressure differentials.

Regular cleanroom validation helps to:

- Detect and identify the source of any harmful contaminant

- Reduce operational downtime and maintenance costs, as the majority of the works are pre-planned and budgeted for

Cleanroom validation is also crucial for regulatory compliance, whether that be ISO 14644 and/or EU GMP Annex 1.

Key steps of cleanroom validation

Qualification of a brand-new cleanroom facility, and in particular, cleanrooms with strict environmental parameters such as those governed by GMP, involves the following steps:

- Design qualification (DQ): The documented verification that the proposed design of the facilities, systems and equipment is suitable for the intended purpose, meeting regulatory and process needs.

- Installation qualification (IQ): The process of evaluating and confirming that the installed cleanroom is consistent with what was specified.

- Operational qualification (OQ): The process of verifying that the cleanroom equipment is achieving the operational parameters specified.

- Performance qualification (PQ): The process of demonstrating that the cleanroom and equipment within it is performing together in an operational state, within specified limits.

- Requalification: Cleanroom validation is not one-time process, so periodic requalification is required to ensure ongoing performance and compliance. This is particularly important after significant changes within a cleanroom, such as process modifications or equipment upgrades/changes.

By completing the various tests involved in cleanroom validation, you can increase the sterility of pharmaceutical products, prevent damage to other equipment within the cleanroom environment (due to exposure to particles), and of course, a reliable test method reduces contamination levels of finished products, too.

Types of cleanroom testing

Cleanroom validation understandably involves a range of specific supporting tests; these include (but are not limited to):

- Airborne particle count testing

- Airflow visualisation testing

- HEPA filter integrity testing

- Environmental monitoring

- Recovery rate testing

- Containment testing

- Temperature and humidity testing

- Pressure differential testing

- Electrostatic testing

Cleanroom validation reporting

Reporting is also an essential part of the validation process. Of course, everyone would like to see ‘PASS’ all over their final report, but these reports should also highlight any failures or non-conformities so that corrective actions may be taken as soon as possible, and the facility can be fully retested.

In the event of any failures being identified, it is recommended that all production should cease, and any corrective actions should be completed before production resumes.

Occasionally, validation failure can be down to operational malpractice such as incorrect gowning, contaminants being brought into the cleanroom by the users and not following standard operating procedures. Upon rectifying these issues by retraining or re-educating users, this may considerably reduce the contaminants, and the cleanroom may then pass the testing.

Find out more about the cleanroom operator training we offer at Connect 2 Cleanrooms here.

In summary

It’s obviously a critical factor that a cleanroom itself should be designed and built to the correct regulation for the processes being undertaken within it, but it is also critical that those using and operating the cleanroom day-to-day understand best practices.

Cleanroom validation is an essential process for maintaining high standards of quality, safety and compliance within a cleanroom, and by adhering to stringent guidelines and regularly validating your cleanroom’s performance, you can be confident in ensuring regulatory compliance in highly regulated industries.

If you’d like to find out more about the cleanroom validation services we offer, click here.

Book a validation appointment

Our cleanroom validation documentation is detailed and auditable. You’ll receive an interim report on the day of testing, followed by the full report within 10 working days. Reporting is aligned with ISO standards and GMP guidelines to meet your requirements and those of any nominated regulatory body (e.g. the MHRA). Let us take the headache out of cleanroom maintenance for you and support you with your cleanroom validation needs.