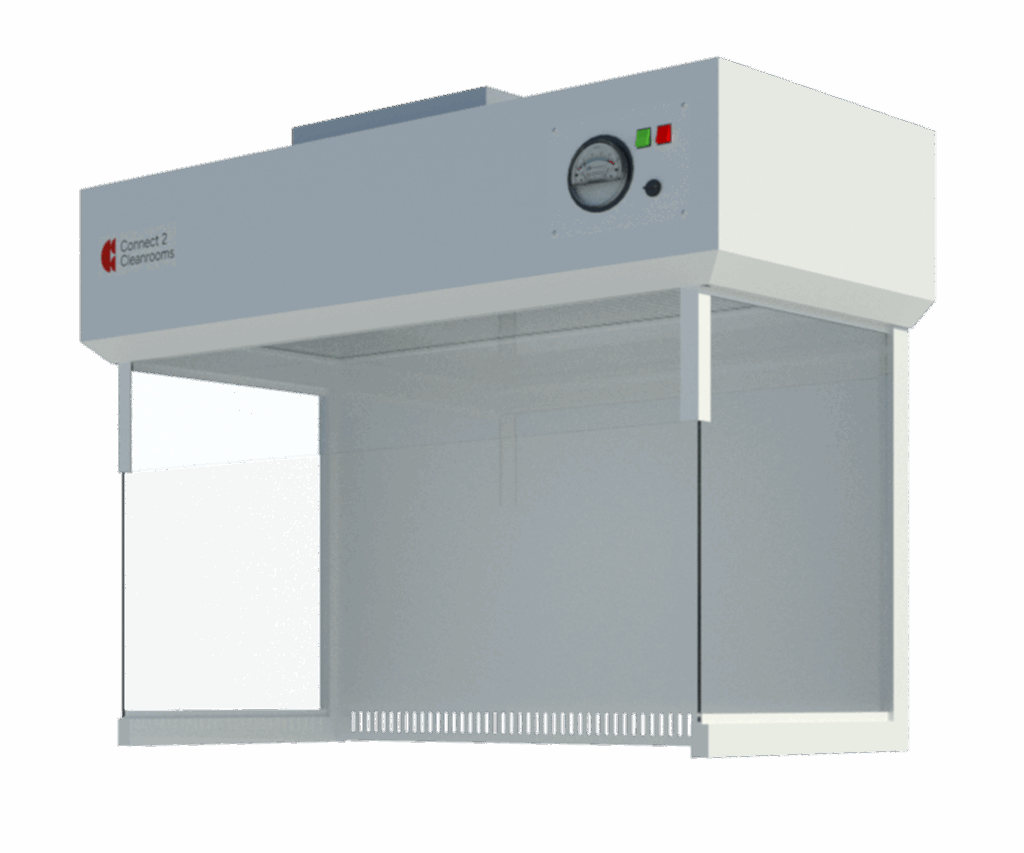

Laminar Flow Cabinets

Our laminar flow cabinets create a compact, highly efficient clean environment ideal for localised applications. By using an even, laminar airflow that removes particles from an enclosed space, they achieve ISO class 5 operating conditions for those handling materials, samples, or products that are sensitive to contamination.

Designed to be seamlessly integrated into your operations, laminar flow cabinets are a crucial piece of equipment utilised in various industries, including pharmaceuticals, microbiology, electronics, and food processing.

What is a laminar flow cabinet?

A laminar flow cabinet (also referred to as a laminar flow unit or laminar flow hood) is a vital piece of cleanroom machinery designed to create a customisable controlled environment within an enclosed space.

Using HEPA fan filter units, a laminar flow cabinet produces a continuous, unidirectional stream of air that creates a contamination-free workstation. Its compact, portable design makes for a convenient solution for creating an ultra-clean environment within a laboratory, manufacturing area, or cleanroom.

The unidirectional airflow protects sensitive products and processes from airborne particulates, making them ideal for industries with stringent regulatory requirements, or even for smaller businesses who need a convenient, cost-effective clean environment solution.

How does a laminar flow cabinet work?

A laminar flow cabinet works by channeling filtered air through a HEPA filter located in the canopy, distributing it in a unidirectional, parallel flow across the workspace.

With air being pushed from the top-down (vertical laminar flow) or pushed from the rear to the front (horizontal laminar flow) larger particles and contaminants are captured in a pre-filter, with smaller contaminants such as bacterial and fungal spores trapped within the HEPA fan filters.

The filtered, clean air is then pushed into the workspace either in a vertical or horizontal flow, preventing particles from entering the controlled environment and contaminating the applications.

Why choose a laminar flow cabinet?

Consistent, contamination-free airflow

User-friendly design

Cost-effective

Dependable performance

Effective filtration

Versatile applications

Laminar flow cabinet specifications

Key features of our laminar flow cabinets

At the forefront of cleanroom technology, our laminar flow cabinet is designed to meet the evolving demands of modern facilities and new processes. With a focus on improving performance, safety, and ease of use, the laminar flow cabinet combines a suite of advanced features that optimise critical airflow and lighting conditions.

- Perforated back panel enhances airflow patterns and ensures uniform and efficient laminar flow

- Vertical airflow direction with 0.3 – 0.7 m/s velocity

- Front sash minimises the entry of contaminated room air, reducing the risk of particulates contaminating your applications

- Enhanced LED strip lights provides improved visibility and working conditions within the enclosure

- 3m(w) x 1.02m (h) provides an optimal, spacious work environment for your applications

- Achieves an ISO class 5 operating environment

- HEPA fan filters

- Casing created using powder-coated steel, ideal for easy cleaning and disinfection

Download the technical specifications PDF

Looking for something a little more bespoke?

Our team of certified design and build experts are here to bring your laminar flow cabinet requirements to life.

Whether you need customised sizing, additional controls, or specialised airflow parameters, we’re here to help you get the most out of your unit and keep production running smoothly.

Ready to start a new project? Request a quote below!

Frequently asked questions

Our laminar flow cabinets are designed to meet ISO 14644-1 class 5 requirements.

Yes! Our laminar flow cabinets can be customised to suite your specific needs and requirements – for more information, speak to one of our experts who’ll be happy to support you with your next project.

Like cleanrooms, laminar flow cabinets require a validation and maintenance process in line with ISO 14644-1 standards, including validation every 12 months and a regular cleaning schedule.

Our laminar flow cabinets are perfectly suited to a wide range of sectors and applications.

Our laminar flow cabinets are a cost-effective solution for introducing a controlled environment, with prices starting at just £3,995.

Vertical laminar flow cabinets work by pushing clean air downwards from the HEPA fan located within the canopy. Horizontal laminar flow cabinets work by pushing clean air across the production space from the HEPA fan filter located within the back panel.

By default, our laminar flow cabinets are designed with vertical airflow, however, our team can support you with alternative airflows if required.