Predesigned Hardwall Cleanrooms

Our predesigned hardwall cleanrooms make it easy to introduce or expand controlled environments without impeding on quality or compliance.

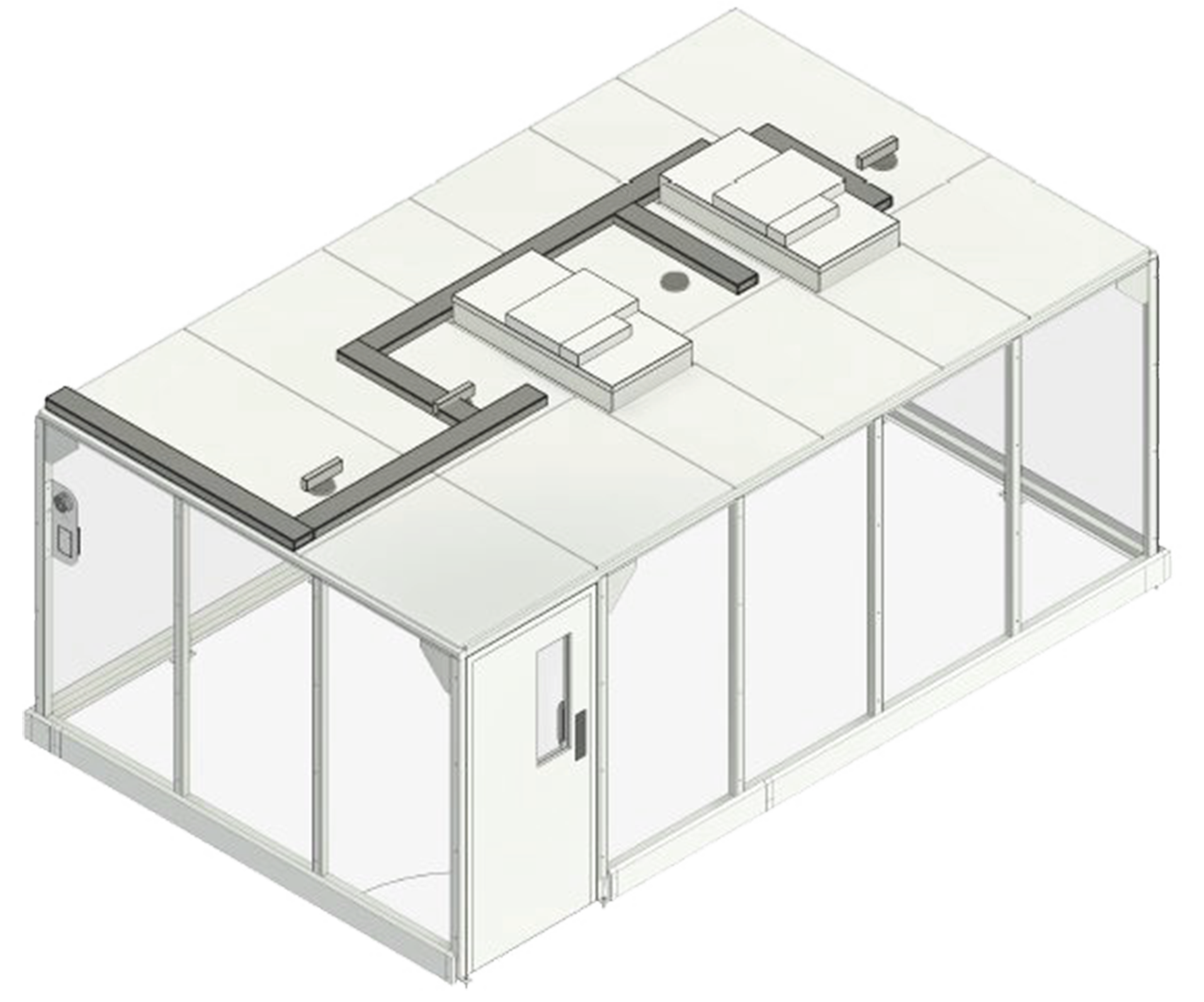

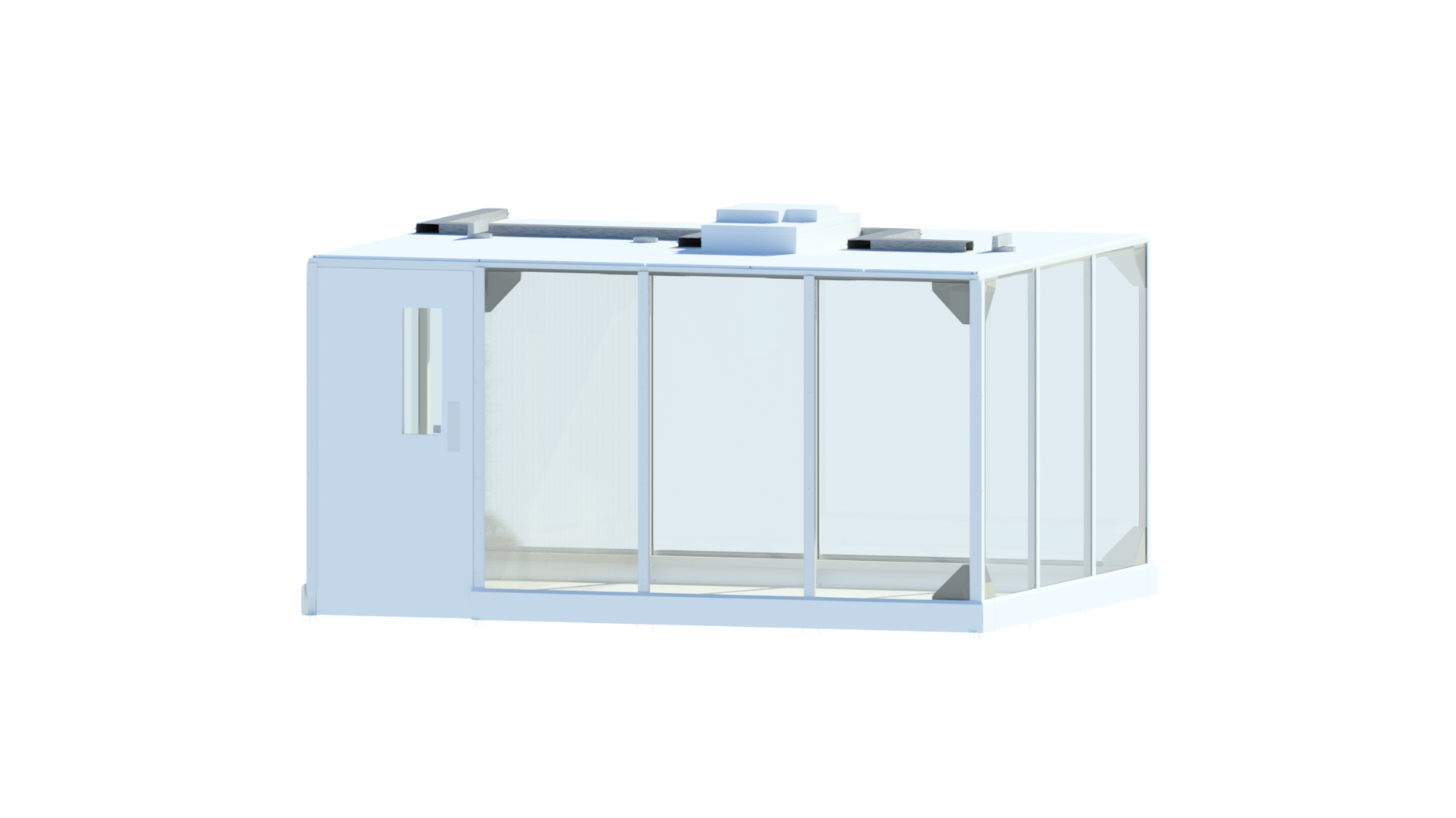

Built with a powder coated steel frame, PETg wall panels, and available in a range of popular sizes, these high-integrity modular cleanrooms are a scalable, future-proof solution for a wide variety of industries and operations.

What are predesigned hardwall cleanrooms?

Our predesigned hardwall range has been designed by you . . .

From years of collaborating with clients worldwide, we’ve created a ready-to-ship solution combining highly-requested sizes and popular specifications – ideal for a wide range of industries.

This means you skip the design phase, reduce lead times, and quickly get started with your production process.

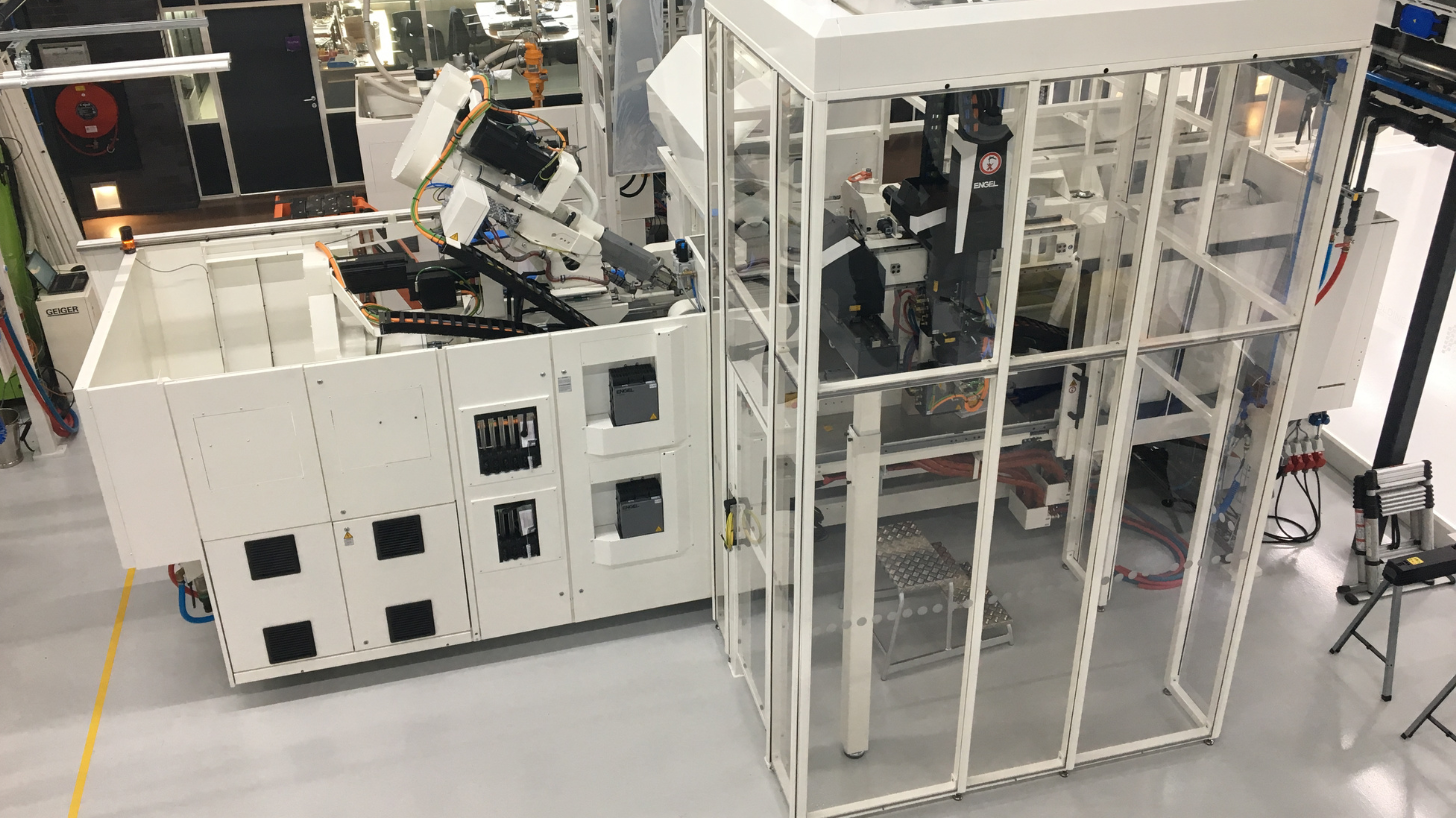

Due to popular demand, hardwall cleanrooms now offer optional door positioning during the build – improving accessibility and orientation. Each hardwall cleanroom has been predesigned with HEPA filtration – creating an ISO 14644-1 compliant environment, perfect for universities, injection moulding, manufacturing, packaging, start-ups, and more.

Ready to start your next project? Contact us below!

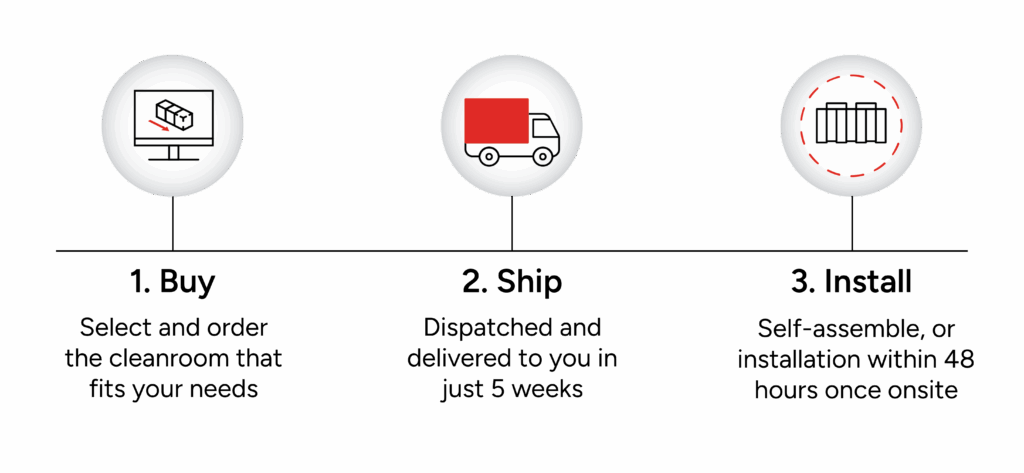

The predesigned cleanroom process

With a predesigned cleanroom, you can get set-up and ready to start your production process in just three, simple steps:

Explore the predesigned hardwall range

Want to explore the predesigned softwall range? Take a look at what’s available here.

CR4

- HEPA filtration: x1

- Size: 4.3m x 3.3m

- Production area: 3.15m x 3.1m

- Change area: 1m x 3.1m

CR5

- HEPA filtration: x2

- Size: 5.4m x 3.3m

- Production area: 4.2m x 3.1m

- Change area: 1m x 3.1m

CR6

- HEPA filtration: x2

- Size: 6.5m x 3.4m

- Production area: 5.3m x 3.1m

- Change area: 1m x 3.1m

Key features of predesigned hardwall cleanrooms

Specifications overview:

- 3 different sizes available.

- 1m x 3.1m integral change area to support gowning protocols.

- Designed to achieve ISO 14644-1 class 7 in production area through positive pressure.

- HEPA filtration 99.99% efficient @ 0.3 micron.

- Right-hand, single leaf door for entrance with optional door positioning.

- Robust steel frame with hygienic coating and PETg hardwall panels for exterior walls.

- Self-assembly kit.

- Optional installation and validation service available.

Download the technical specifications PDF:

Why choose a predesigned hardwall cleanroom?

Reduced lead times

Speedy construction times

Cost effective

Integrated change area

ISO class 7

Popular sizes

Time-lapse video of a 6m x 3m predesigned cleanroom: 48 hours in 60 seconds

Connect 2 Cleanrooms was appointed by Lancaster & Morecambe College, to provide a predesigned cleanroom to be used in its Engineering Department, to allow students the opportunity to gain experience of working within a cleanroom environment.

Read the full case study here.

Setting up your new hardwall cleanroom just got easier

Complementary cleanroom starter packs

Not only were we the first ecommerce provider of cleanroom consumables and furniture, we’ve also been designing, building, and maintaining hardwall cleanrooms for over 20 years. With over two decades of working closely with our clients, we’ve learnt what it takes to effectively and consistently create and maintain an optimal controlled environment.

To help make setting up your new hardwall cleanroom even easier, we’re now offering a complementary Cleanroomshop starter pack filled with essential cleanroom items. From cleanroom clothing, disinfectants, and contamination control solutions, our specialists have hand-picked the most popular and sought-after items. Plus, you’ll also receive a £50 voucher and exclusive discounts to spend on Cleanroomshop for your next order!

When you partner with us for your next hardwall project, we’ll do more than just build your cleanroom; we’ll provide you with the tools and essentials to optimise your production process.

Looking for something a little more bespoke?

Connect 2 Cleanrooms offer a complete cleanroom design and build service. Our bespoke modular cleanrooms create classified environments to protect processes from harmful airborne contamination – reducing failure rates and helping organisations get it right first time.

We manufacture a cleanroom of a few square meters, to hundreds of square meters, with the ability to install bespoke designs around existing machinery where needed. The modular design means that our cleanrooms can be extended or relocated, so you can grow your production area as demand increases.

Ready to start a new project? Request a quote below!

Frequently asked questions

Yes! Due to the way the steel frame is designed, you have multiple options for door positioning without the need for any design modifications. We also offer additional custom features including transfer hatches and upgraded ISO classifications. However, these enhancements may result in this becoming a custom-built project, which could extend lead times.

Our predesigned hardwall cleanrooms can be delivered in just 5 weeks and installed within 48 hours of our engineers arriving onsite.

Predesigned hardwall cleanrooms should be validated in line with ISO standards – it’s recommended that cleanrooms are validated at least once every 12 months.

Our predesigned hardwall cleanrooms are made using robust steel framing with a hygienic coating, and PETg hardwall panels for exterior walls.