Hardwall Cleanrooms: High-Integrity and Versatile

Hardwall cleanrooms are a popular choice if you’re looking for an ISO class cleanroom solution to protect your processes from environmental contamination.

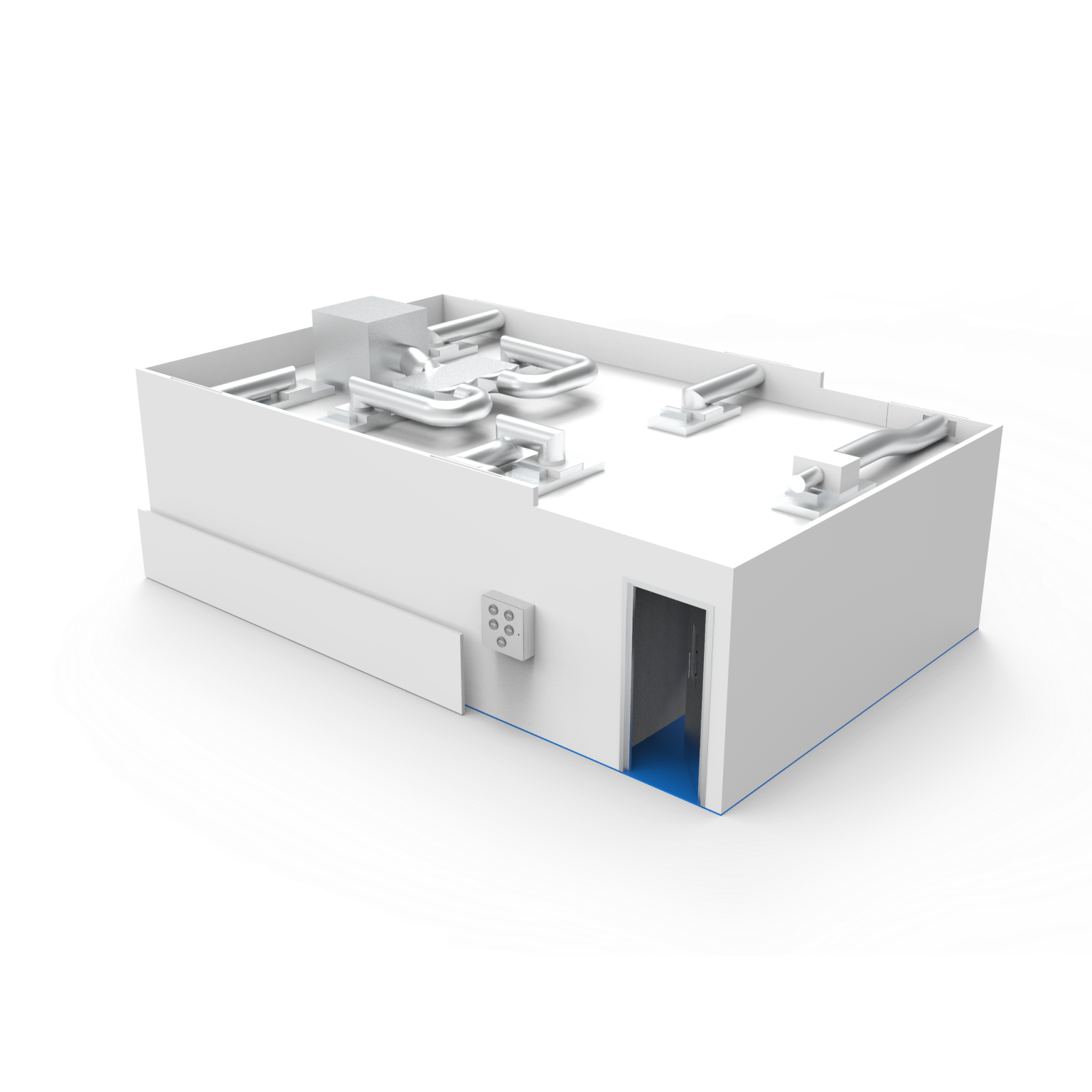

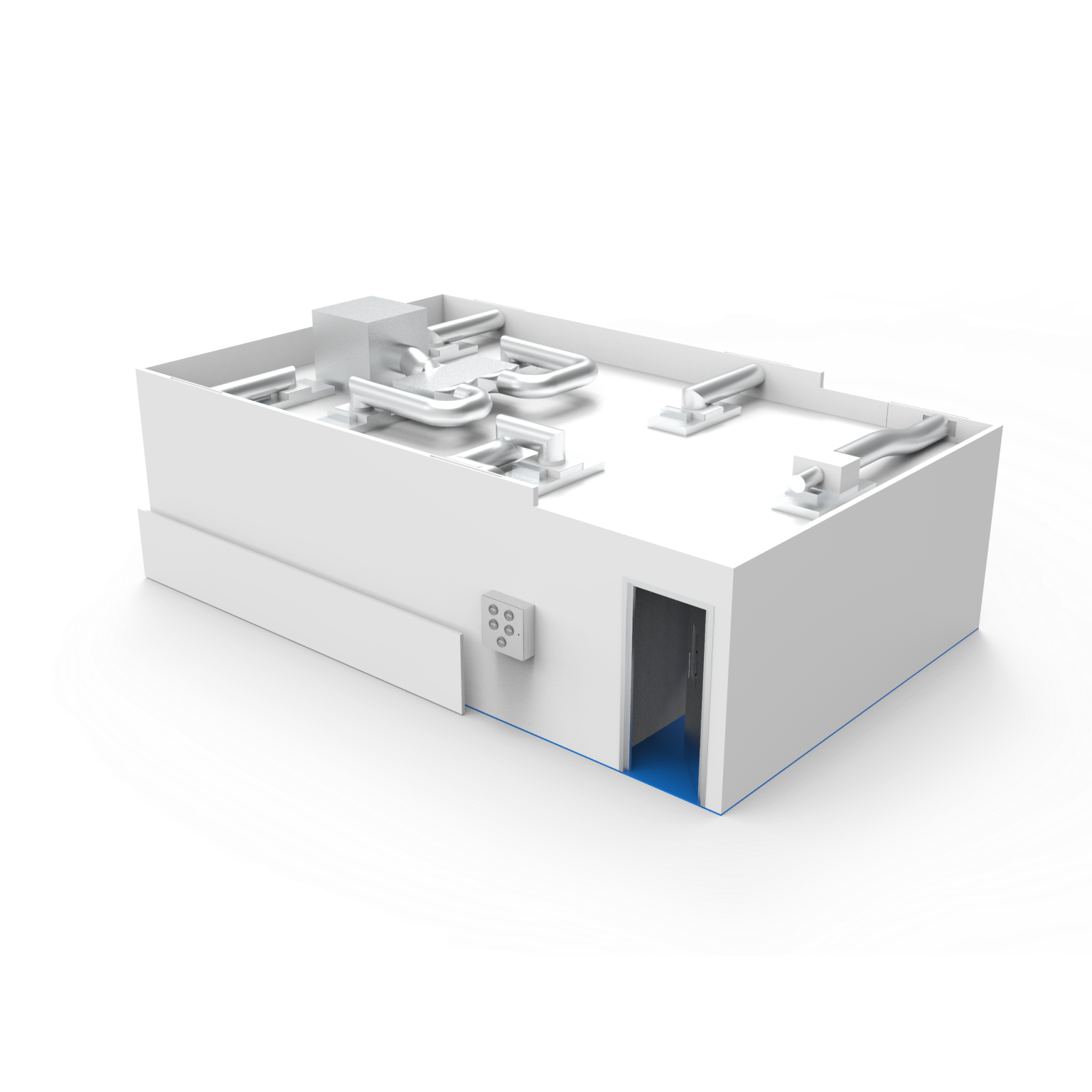

Hardwall PVC or PETg panels are attached to a powder coated steel frame to create a high-integrity modular cleanroom wall construction. These robust walls enclose the clean area, keeping your working environment compliant.

In this blog, we’ll look at the benefits of hardwall cleanrooms, their ideal applications, and our predesigned range.

Benefits of hardwall cleanrooms

Versatile design options

We offer a wide range of design options to meet your specific requirements. From size and layout to customisation & configuration options, our cleanrooms can be tailored to meet your exact needs.

Regulatory compliance

Hardwall cleanrooms feature HEPA filtration and customisable environmental control parameters. This means that they can be used by industries that are governed by strict ISO 14644-1 regulations.

Advanced contamination control

With advanced features like positive pressure, laminar flow, change areas and pass through hatches, our hardwall cleanrooms create a controlled ISO 5-8 environment that minimises the risk of contamination.

Scalable, robust and durable

Our hardwall cleanrooms are built using robust, impact resistant & durable materials. They can also be deconstructed and relocated or expanded in response to changing business needs, making them a fantastic, future-proofed scalable option.

Hardwall cleanroom applications

We recommend hardwall cleanrooms for all sizes of cleanrooms, so whether you’re looking for a small first cleanroom for your processes, or a larger space for expanding production, we can help.

Hardwall cleanrooms are particularly popular for medical device manufacturing, electronics and semiconductor construction, as well as automotive and aerospace applications.

Case studies

Find out more about some of our hardwall cleanroom projects:

15m² hardwall cleanroom for Dubai-based technology company

We were appointed to create a cleanroom solution to assist XPANCEO in developing smart contact lenses that display images directly onto the eye.

ISO class 7 cleanroom for Craft Prospect

We supplied Craft Prospect with a 12m² hardwall cleanroom from our predesigned range.

182m² CBD cleanroom for Orange County CBD

We designed and built a custom ISO class 7 cleanroom to produce CBD products.

Hardwall cleanroom with automated HEPA-lite™ canopies for injection moulding process

We designed and built a cleanroom system that includes automated clean-air HEPA-lite™ canopies, controllable by a user-friendly touch screen interface.

Predesigned hardwall cleanrooms

Our predesigned range of ready-to-assemble cleanrooms are a swift and cost-effective contamination control solution for a wide range of applications.

Predesigned to popular sizes and specifications, these cleanrooms have a quick turnaround from order placement to delivery and can be constructed in as little as 48 hours.

Perfect for use as an entry-level solution, or for a quick way to react to growing production demands.

Ready to start a new project?

We are a modular cleanroom manufacturer. Our cleanroom design and build specialists have experience working with customers in all kinds of industries, achieving great results time and time again. We’d love to hear about your next project!