Why Choose a Modular Cleanroom?

When commissioning a new cleanroom, time, flexibility, and cost are always high on the priority list. That’s where modular cleanrooms excel. Unlike traditional builds, modular cleanrooms are designed with adaptability and efficiency in mind, making them the go-to solution for businesses across a wide range of industries.

What are modular cleanrooms?

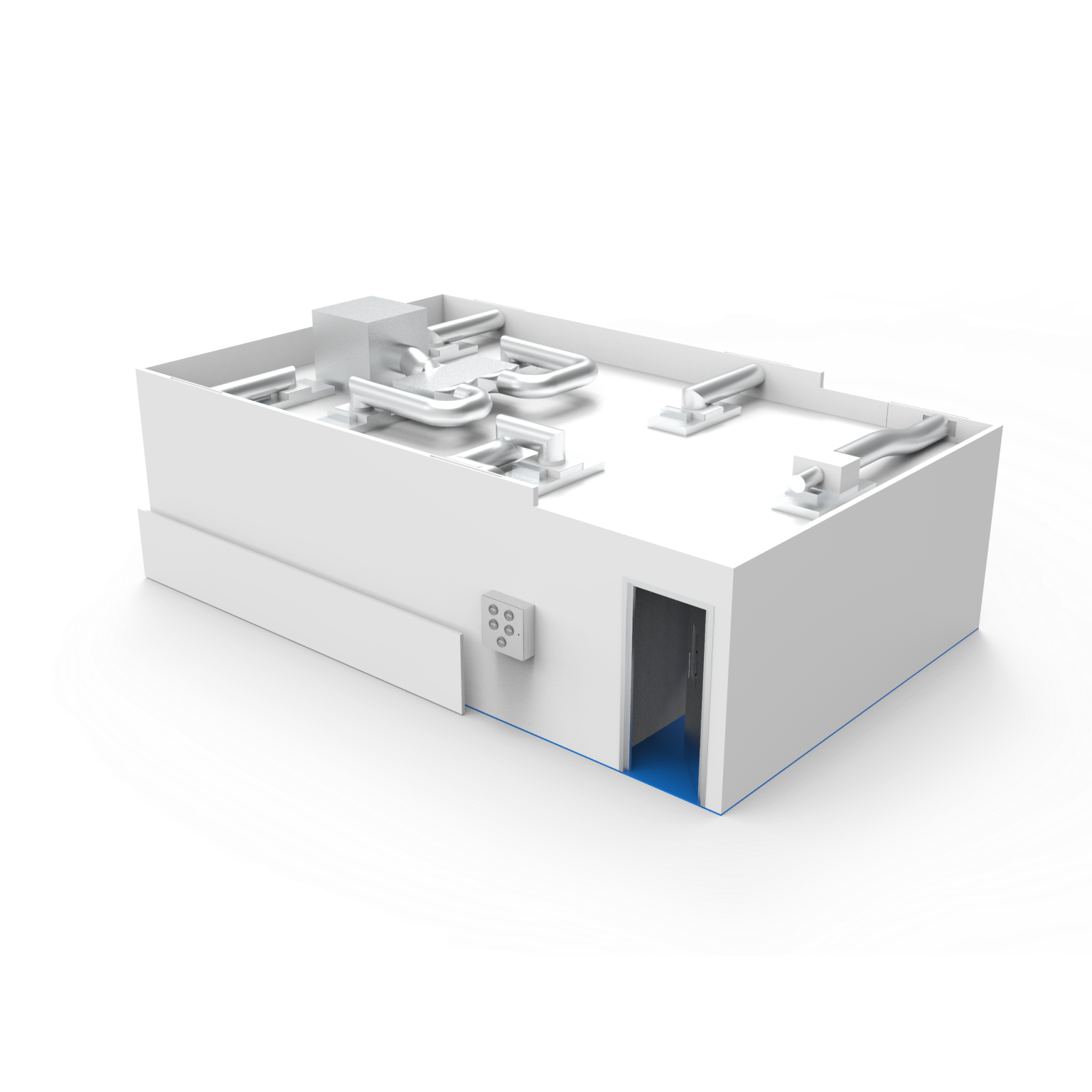

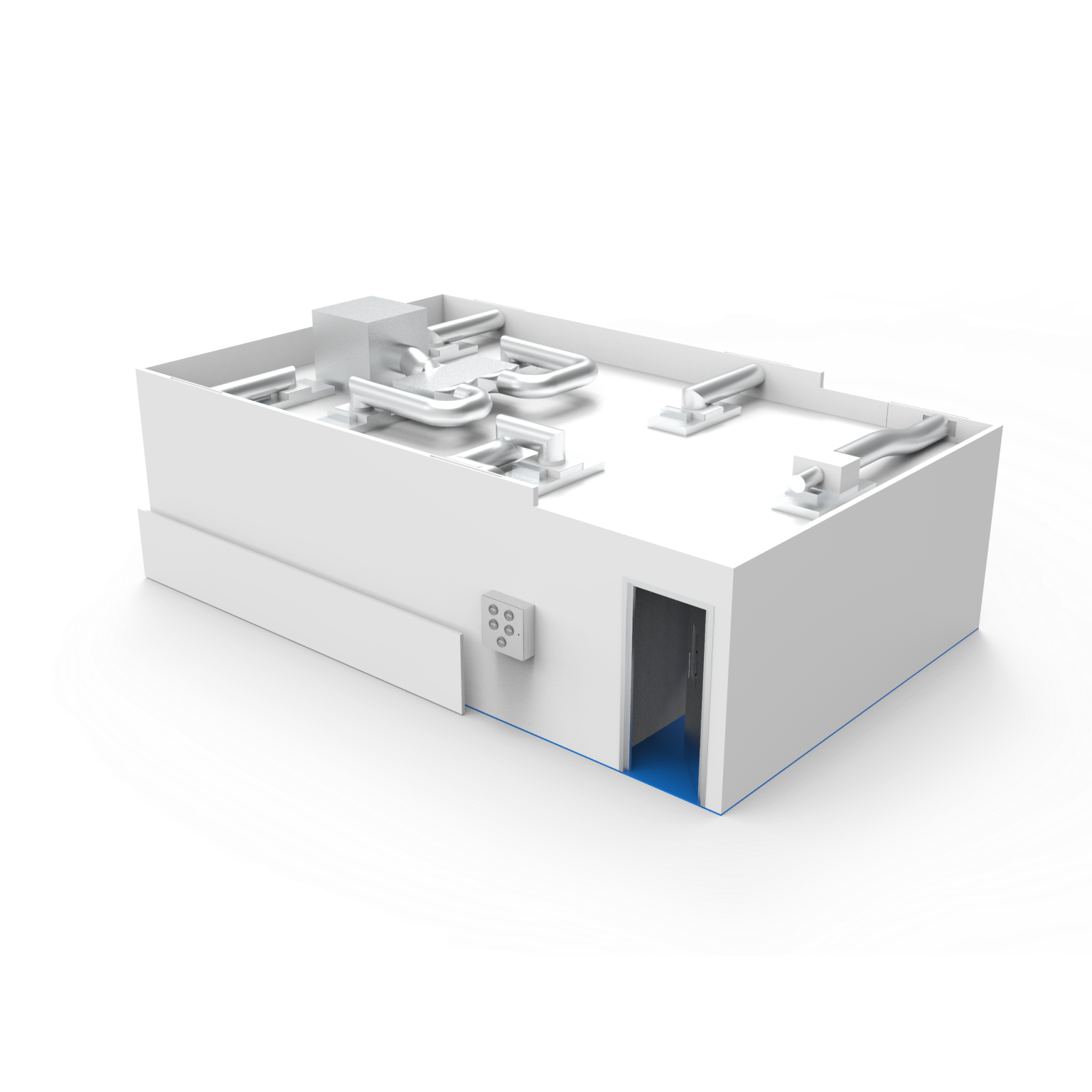

A modular cleanroom is a controlled environment built from prefabricated components that are manufactured off-site. Modular cleanrooms are designed to meet ISO and GMP classifications, ensuring strict control over airborne particles, temperature, humidity, and pressure.

Modular cleanrooms are installed onsite using premanufactured components, including wall and ceiling panels, and in some cases special features including pass-through hatches, air locks, air showers, and material transfer points.

Because they’re modular, they can be quickly designed, installed, and adapted. They combine the robustness of a permanent structure with the flexibility of a temporary installation, meaning you don’t have to compromise on performance or quality.

The benefits of modular cleanrooms

- Speed of delivery: Modular cleanrooms can be installed in a fraction of the time compared to traditional construction, with minimal disruption to your operations.

- Scalability: A modular cleanroom can be expanded, modified, or even relocated as your production processes evolve.

- Customisable: From specialist equipment to unique features, modular cleanrooms can be tailored to meet the exact requirements of your applications.

- Cost-effective: With a smaller, controlled environment, airflow and other conditions are easier to regulate. The result is lower energy consumption and reduced running costs.

- Compliance: Modular cleanrooms can be designed and built to meet ISO 14644 or GMP standards.

Different types of modular cleanrooms

Hardwall cleanrooms

These are a popular choice for those looking for an ISO-compliant cleanroom solution. Hardwall cleanrooms are built using robust PETg wall panels to create a secure, controlled space with excellent durability and precise environmental control.

Softwall cleanrooms

These are ideal for those looking for a lightweight and flexible ISO-certified cleanroom environment. Softwall systems are installed with PVC panels, providing a cost-effective option with rapid installation.

Monobloc cleanrooms

A premium solution with seamless, flush finish options, offering the highest levels of hygiene and contamination control making them ideal for higher class ISO and GMP environments.

What industries use modular cleanrooms?

The variety and versatility of modular cleanrooms make them ideal for a range of sectors and applications requiring a controlled environment. Modular cleanrooms are used whenever control and compliance are essential, with some of the top industries using this option including:

Pharmaceuticals

Electronics and semiconductors

Injection moulding

Medical and healthcare

Modular cleanroom client story

In 2011, when medical plastics manufacturer, Optimold, needed a cleanroom solution to create a controlled environment around existing machinery, they chose a modular system from Connect 2 Cleanrooms.

Over a decade later, we’ve supported Optimold with developing a range of controlled environments as their production processes evolved, with a total of seven modular cleanrooms housing injection moulding machines. This continues to give them the flexibility and performance required to maintain quality and compliance in a demanding industry.

Frequently asked questions

Yes, modular cleanrooms can be extended, modified, or even dismantled and relocated to new facilities.

Costs vary depending on size, classification, and features. Modular cleanrooms are typically more affordable to run thanks to energy efficiency.

From compact units to large-scale facilities, modular cleanrooms are designed to fit your available space.

Modular cleanrooms can be designed and built to meet a wide range of ISO and GMP classifications.

Just like any other cleanroom, modular cleanrooms require regular cleaning and disinfection protocols to ensure a contamination-free environment. Depending on your ISO or GMP classification, it is best practice (or in some cases, mandatory) to conduct annual cleanroom qualification or validation of your facility.

Start a project with us

Modular cleanrooms are fast, flexible, and cost-effective, making them the ideal solution for organisations that need to balance performance with adaptability. If you’re considering a new cleanroom, reach out to a member of our team who can help design and deliver a system that fits your exact requirements.